Inside Seating matters

Tour Seating Matters' world-class lean factory, revealing how visual management, total ownership, and aesthetic attention create a calm, productive workplace where employees genuinely want to be.

Seating Matters is an Irish manufacturer specializing in advanced seating solutions, renowned not only for their innovative products but for their exceptional lean manufacturing transformation. It is their mission to improve millions of lives a year in a sustainable manner.

Under the leadership of Ryan Tierney (Lean Made Simple), the company has become a benchmark destination for lean practitioners worldwide, demonstrating how principles like total ownership, visual management, and respect for people can create a truly world-class operation. Their facility showcases sophisticated systems including Heijunka load-leveling, sequenced production flow, comprehensive Kanban controls, and GembaDocs integration throughout every process.

Sector: Healthcare and Medical Care

HQ: Ireland

Customer since: 2022

SOPS: 500+

So much to show,

we couldn't pack it into one page!

Scroll a little and you will find short short highlights of the tour of Seating Matters, but to do their culture, business and team justice, we’ve created three separate tour pages to give this lean team their full credit.

Full Tour: 25 mins, 30 LEAN INSIGHTS

Delve into the whistle stop tour of seating matters in this in depth article, complete video and full run down of ways Seating Matters are lean through every stitch of the business.

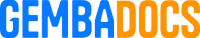

ClEAN And LEAN Canteen with no cleaners

Open any cupboard – cups perfectly centered. Check the kitchen at 4:30 PM Thursday – spotless without supervision. No dedicated cleaners, just a self-managing rota system and a culture where everyone owns their space.

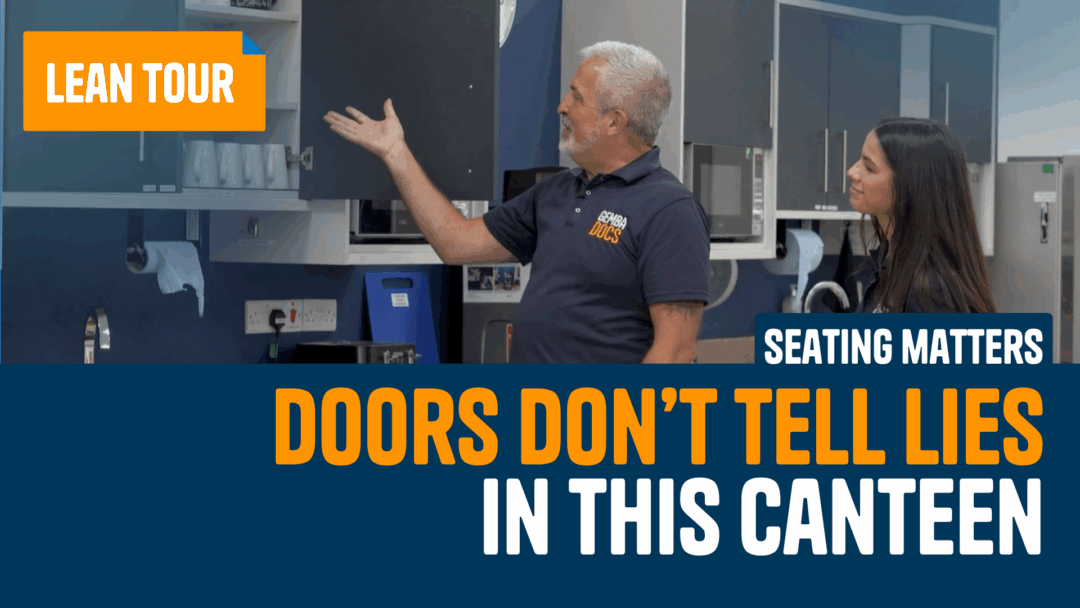

A kanban system so good it's like lego

From two-bin systems with GembaDocs instructions to red-coded management-approval Kanbans, weekly ordering racks organized by supplier, and 360-degree location signage, Seating Matters’ visual management is a masterclass.

Some highlight clips below…

SOPs

Preventing Knowledge Loss: Documenting CNC Operations

Paddy shares how Seating Matters uses GembaDocs to tackle a common manufacturing challenge: when only one person knows how to operate expensive, complex machinery. With four years of CNC experience, Paddy created a simple six-step guide that enables less experienced team members like Ben to confidently start up the wood CNC machine, even with just three weeks of training.

Key Takeaways:

- Document tribal knowledge before it becomes a bottleneck – When only one person knows how to operate critical equipment, that creates a vulnerability in operations and limits flexibility in staff coverage.

- Simple documentation has big impact – A straightforward six-step SOP can make the difference between an expensive machine sitting idle and a team member being able to operate it confidently during cover periods.

- Experience doesn’t need to leave with the person – By capturing what experienced operators know “in their head” into an SOP, that knowledge becomes accessible to the entire team, reducing training time and building operational resilience.

SOPs

Can Someone Start a Machine They've Never Seen Before?

Alisha puts GembaDocs to the ultimate test: operating a machine she’s never seen or used before. With nothing but the digital SOP to guide her, she walks through each step: from switching to the “on” position to pressing the start button and waiting for the six flashes that confirm success. It’s a powerful demonstration of how clear, visual documentation can enable anyone to perform tasks confidently, even without prior experience or training.

Key Takeaways:

- Step-by-step clarity builds confidence – Breaking down the process into specific, sequential actions (turn this switch, press that button, wait for six flashes) removes ambiguity and empowers users to act without hesitation.

- Visual documentation accelerates onboarding – New starters can become productive immediately when they have access to clear, accessible instructions at the point of work, dramatically reducing the time and resources needed for traditional training.

RETRAINING

"I Don't Have to Stop Anyone to Ask"

Micky explains how GembaDocs has revolutionized cross-training at Seating Matters. Trained across 7-8 different stations throughout the factory, he, and other team members, can move between areas confidently without interrupting colleagues for help. When returning to a station after time away, the constantly updated step-by-step guides ensure they’re always working with current processes, even when things have changed; making both their job easier and the factory more flexible.

Key Takeaways:

- Living documents adapt to changing processes – Because GembaDocs are constantly updated, operators always have access to current procedures, eliminating confusion when processes evolve over time.

- Cross-training becomes scalable – With SOPs at every station, one person can learn multiple areas independently, removing the traditional bottleneck of needing experienced operators to train others one-on-one.

- Self-sufficiency reduces operational interruptions – When operators can reference documentation instead of asking colleagues for help, it maintains productivity across the factory by keeping everyone focused on their own work while still enabling flexibility in staffing.

SOPs

"Done the Same Every Time" - How SOPs Guarantees Packaging Consistency

Kira explains how GembaDocs has transformed the packaging process at Seating Matters by providing team members with clear, step-by-step guides that ensure consistency for customers. New team members have a reliable reference point as they learn, while experienced operators still have a backup resource whenever needed. The result is standardized quality and easier training across the board.

Key Takeaways:

- Standardization drives customer consistency – When every operator follows the same clear steps, customers receive the same quality experience every time, regardless of who packages their product.

- Documentation supports the learning curve – New operators can reference SOPs until procedures become second nature, accelerating their path from novice to confident practitioner without constant supervision.

- A safety net for everyone – Even experienced team members benefit from having documentation available as a backup, ensuring quality doesn’t slip during busy periods, after time away, or when unusual situations arise.