POSTS

Seating Matters Kanban Tour: Total Ownership and Visual Control

This well-developed Kanban system ensures materials arrive on time, prevents stockouts, and allows anyone, even visitors, to understand inventory status at a glance.

Seating Matters Full Lean Tour – 25 Mins, 30 Insights!

World-class lean factory, revealing how visual management, total ownership, and aesthetic attention create a calm, productive workplace where employees genuinely want to be.

Lean Tours

Inside Seating Matters

Tour Seating Matters’ world-class lean factory, revealing how visual management, total ownership, and aesthetic attention create a calm, productive workplace where employees genuinely want to be.

Inside Fat American Manufacturing

Watch how simple visual management systems eliminate purchasing bottlenecks while turning day-one employees into active contributors who build their own SOPs.

Inside Hampton Conservatories

From magnetic scheduling boards to QR code training systems, here’s how Hampton eliminated waste and turned every problem into an improvement opportunity.

Inside British Rototherm Group

Supercharged with visual control, SOPs, AI and continuous improvements, this tour delves into every operational corner of the British Rototherm Group.

Customer Stories

Seating Matters Kanban Tour: Total Ownership and Visual Control

This well-developed Kanban system ensures materials arrive on time, prevents stockouts, and allows anyone, even visitors, to understand inventory status at a glance.

Seating Matters Full Lean Tour – 25 Mins, 30 Insights!

World-class lean factory, revealing how visual management, total ownership, and aesthetic attention create a calm, productive workplace where employees genuinely want to be.

Seating Matters Canteen Tour: Cleaner and Leaner Than Most Homes

From hotel-quality coffee machines to dual dishwashers to perfectly centered cups with placement guides – when leadership cares about these details, employees care about product

Lean - Tours, Stories and Insights

Seating Matters Kanban Tour: Total Ownership and Visual Control

This well-developed Kanban system ensures materials arrive on time, prevents stockouts, and allows anyone, even visitors, to understand inventory status at a glance.

Seating Matters Full Lean Tour – 25 Mins, 30 Insights!

World-class lean factory, revealing how visual management, total ownership, and aesthetic attention create a calm, productive workplace where employees genuinely want to be.

Bringing value to manufacturing organizations with simple tools that empower frontline workers, supervisory teams, and senior management, in supporting calm productive flow within their processes.

Lean Cave Resources

Courses

Industry leading courses that support learning lean, self-development and workforce empowerment.

Guides

A handful of guides that help you understand SOPs, working instructions and the GembaDocs platform.

Useful stuff!

Useful stuff from GembaDocs HQ lean journey, finds on the internet and shares from GembaDocs users!

GembaDocs Updates

Product Update: Multi-Lingual SOPs, Smarter SOPs, Smarter Skills – September 2025

From multilingual documents to customizable cards, skills tracking, and analytics upgrades, these changes are built to simplify work for teams on the shop floor and in the office.

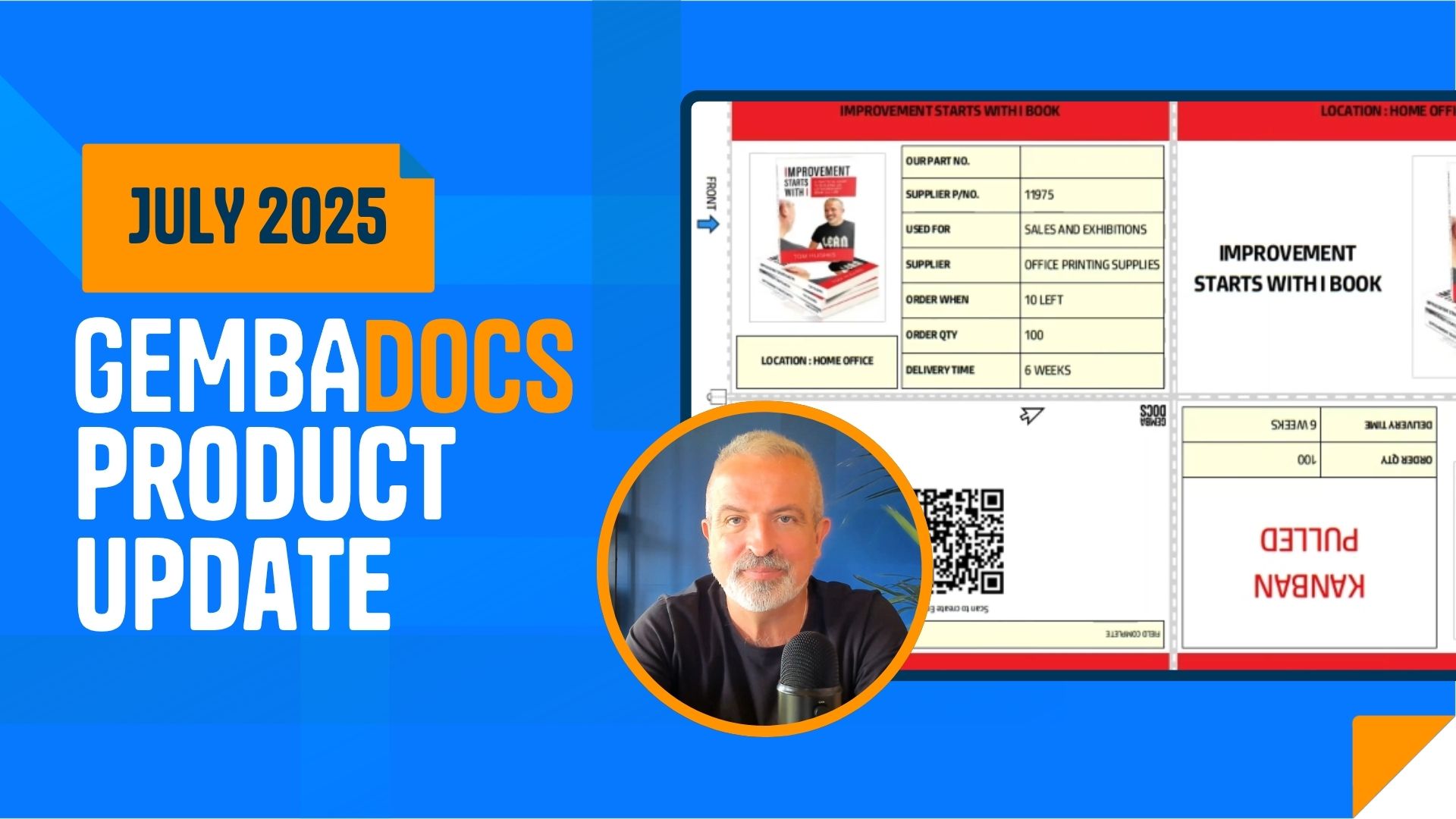

Product Update: July 2025 – Kanban Major Improvements, SOP Draft Mode & QR Changes

We introduce Kanban email automation, SOP draft capabilities, mobile UI improvements, and QR code changes. Plus French language support now available.

The Truth About Implementing SOPS – Q&A With Brian Meyers, Fat American Manufacturing

In this Q&A, Brian shares the exact strategies they used to engage frontline workers, simplify documentation, and scale SOPs across every department.

Create calm productive workflow & see results

SOPs & Kanban

Seating Matters Kanban Tour: Total Ownership and Visual Control

This well-developed Kanban system ensures materials arrive on time, prevents stockouts, and allows anyone, even visitors, to understand inventory status at a glance.

Seating Matters Full Lean Tour – 25 Mins, 30 Insights!

World-class lean factory, revealing how visual management, total ownership, and aesthetic attention create a calm, productive workplace where employees genuinely want to be.

Case Study: GembaDocs at British Rototherm

Discover how British Rototherm embeds Lean from the moment you walk in: safety point-of-use, brilliant visual controls, daily routines, “house rules”, and even AI agents

Empower your workforce with GembaDocs